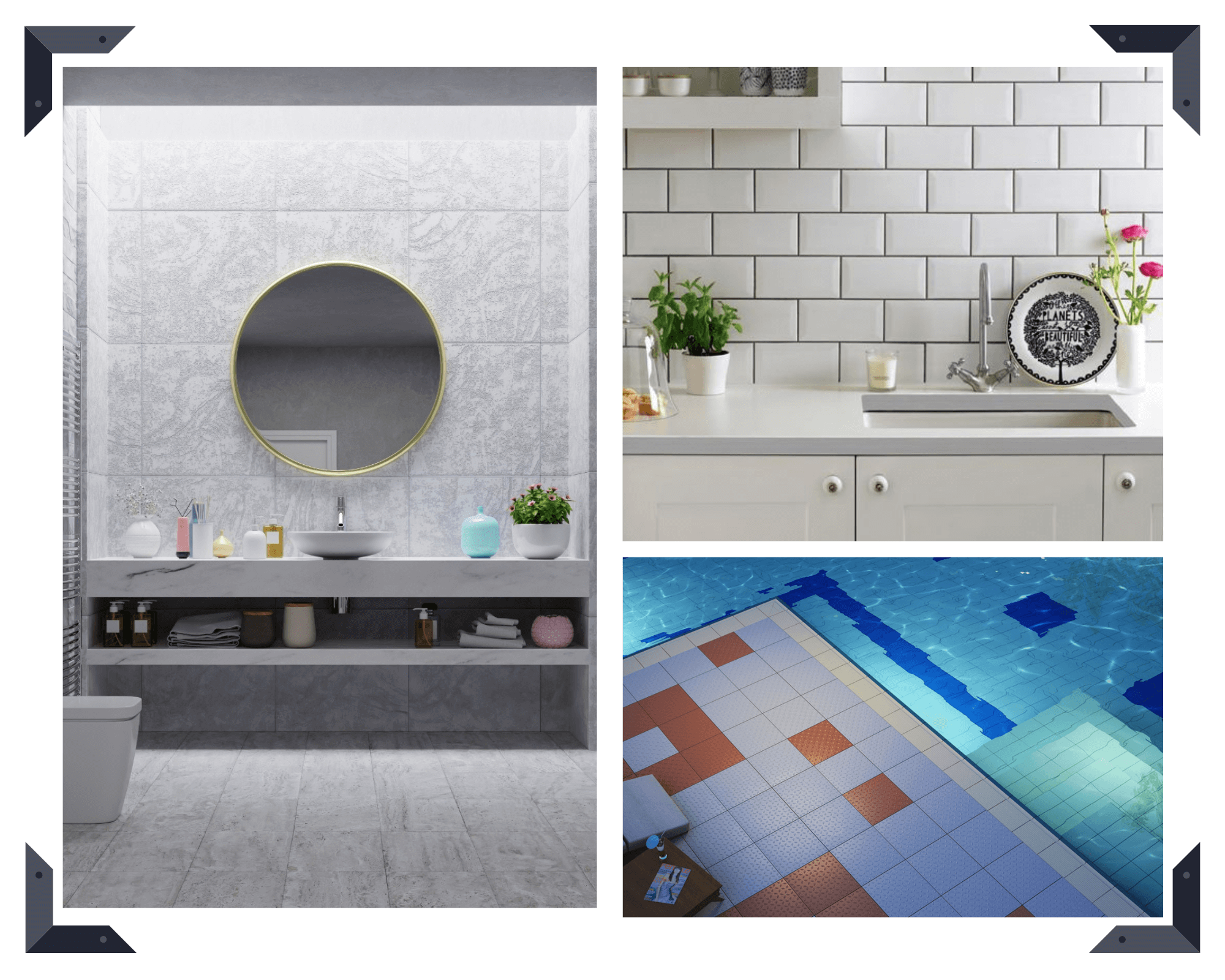

Epoxy grout is a product that consists of three components: a resin, a hardener, and an aggregate. The resin mix with the hardener must be done separately, before mixing with the aggregate. The mixing ratio of the resin with the hardener is very precise. Now we want to show you the benefits of epoxy grout, but first of all, we want to explain to you what are cement and epoxy grout

Cementitious joints are made up of mortars with a cement-based binder and have always been used in residential environments. They are divided into two classes CG (cementitious grouts): CG1 is the normal class, CG2 is the improved class. We can add two other classes to these: class A, which is resistant to abrasion, and class W, which is water repellency.

In residential settings, CG1 type cement grouts are sufficient; On the other hand, when a floor is subject to high traffic and wear, to continuous variations in humidity and/or temperature, or a continuous flow of water, it is necessary to opt for grouts that have a CG2 class and preferably also a class. A and W.

Unlike previous years, cementitious grouts, although not completely the same as epoxies, have good performances in terms of anti-fluorescence, water repellency, resistance to mould, reduced emissions of volatile organic compounds (VOC), and colour resistance to the length of the time.

Epoxy grouts are based on epoxy resins. Due to the remarkable elasticity, water repellency, resistance to abrasion, resistance to chemical products and mechanical stresses, being stain-resistant, efflorescence-free, anti-mould, antibacterial, epoxy grouts are widely used in all those environments defined as "technical", that is to say, subject to high flow rates, wear, continuous thermal and humidity variations and that require a high level of surface hygiene. Unlike cementitious grouts, epoxy grouts are classified according to a single class, RG (resin grouts), which has the abovementioned characteristics.

The prices of epoxy grout are higher than the prices of cement grout. But, given that large ultra-thin formats, such as laminated stoneware, there is a certain reduction in costs, since the amounts of grout depend on the width, length, and thickness of the tile as well as the width of the joint.

Benefits of Epoxy Grout

Epoxy grouts used to be used only for industrial purposes, and the great popularity among consumers was only recently acquired. Fill the space between the tiles as much as possible, thus avoiding the contamination of the joints, the formation of mould and fungus on them. The trowelling mix has several characteristics that determine its popularity for use in construction.

Advantages of Epoxy

- It can be used instead of glue.

- The mechanical resistance has increased. Thanks to this, the tile serves much longer than with the cement grout.

- Leaves no water or steam. Epoxy grout provides reliable protection against pathogenic mould and mildew, which is not unimportant, as mould is harmful to human health.

- Resistant to dirt. The grout does not turn black and does not change colour, which indicates its high decorative qualities.

- It is not susceptible to chemical attacks, it does not enter into dangerous reactions with other chemical elements.

- These are some reasons why Epoxy grout is the best option for work. To see the best prices and quality of epoxy grout, check out our products:

How to Apply Epoxy Grout

The application of epoxy grout differs significantly from that of cement grout. It is critical that you acquaint yourself with the peculiarities of dealing with epoxy material before beginning construction work. It is critical to correctly prepare epoxy grout's composition before using it; the quality of the job will be determined by this.

When mixing, it's crucial to avoid forming a high number of bubbles in the mixture, since this will result in a heterogeneous structure and, as a result, colour loss. The final mixture should be stored in a clean container to avoid the grout from becoming uneven in colour.

It is not recommended to cover the entire surface in one go; instead, complete the application in a 50 to 80 square centimetre sector before moving on to another comparable region. Allowing too much time to pass between washing the tiles and removing extra grout from the corners of the walls is not a good idea.

Use a firm/soft rubber grout float to apply the mixture between the seams. Instant trowel curing lets you work between seams right after application. Excess grout may be washed away right away. You can wash the grout with water or non-concentrated chemicals; excessive concentrations can affect the colour of the grout. A specific hard sponge may be used to remove grout quickly and effectively.

Residual epoxy resin cleans up faster than a monkey. They can be removed later, but it will be a more involved and comprehensive operation.

It is crucial to keep in mind that when you first start dealing with resin, its composition may appear to be overly thick. It is simple to work with resin if the resin and hardener are thoroughly combined.