What is Latex SBR:

Latex SBR is a liquid additive used in construction project and can be SBR (styrene-butadiene rubber) or Acrylic base.

What is SBR?

Styrene-Butadiene elastic (SBR or Styrene-butadiene) is an engineered rubber involving styrene and butadiene monomers. The arbitrary copolymer has characteristics like natural rubber and contains: Styrene content in the scope of 10-25% adds to great wearing and holding qualities.

While the butadiene unit is made roughly 60 to 70% trans-1,4; 15 to 20% cis-1,4; and 15 to 20% 1,2 configuration for the polymer at 50°C.

The utilization of latex (styrene-butadiene rubber) in concrete, cement, plaster has been expanding in substantial development (construction) and repair work because of its advantages to flexure strength, adhesion and impermeability

Acrylic Latex:

Acrylic latex is more expensive compared to SBR latex. Acrylic latex has higher performance characteristics. Acrylic latex has higher usage in waterproofing due to its UV stable properties.

Why do we see an early crack on our walls and floors?

Concrete is likely the most widely utilized material on the planet invigorated its, primary solidness, strength, financial contemplations and low-level upkeep and Portland cement, presumably the main constituent of concrete, is a flexible and moderately low-cost material.

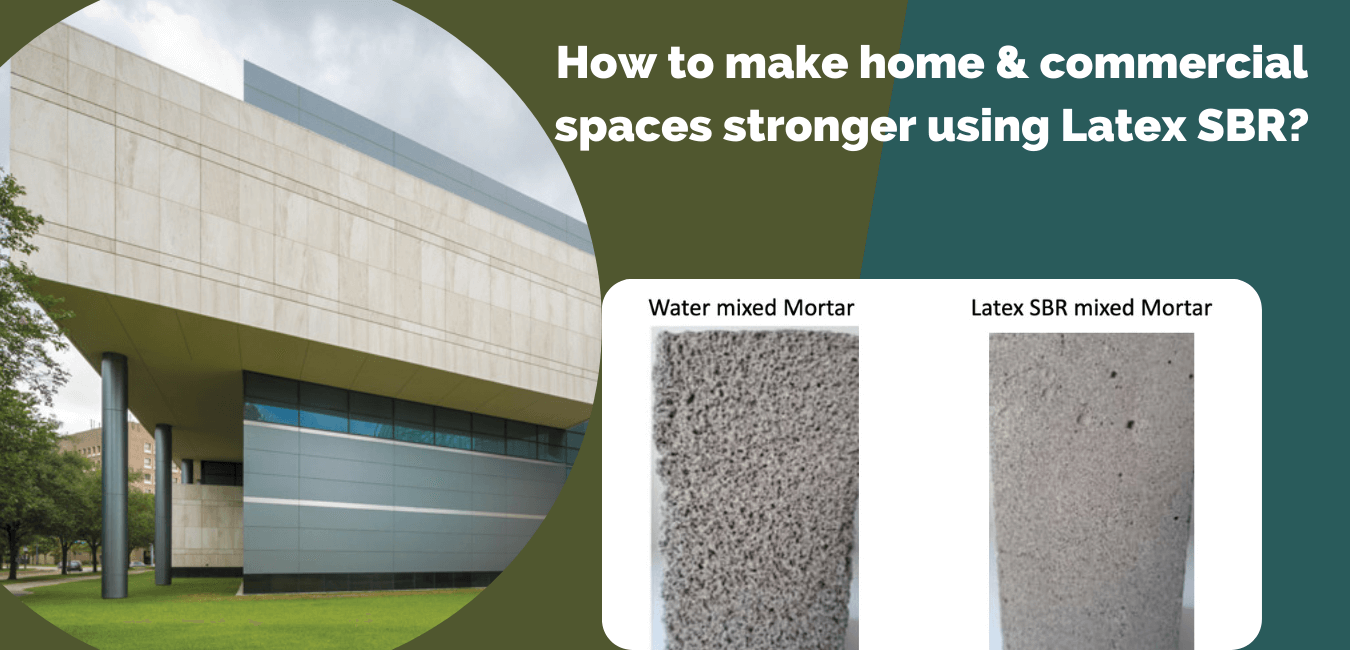

Nonetheless, the principal challenge comes if these materials are blended only with water in a construction project this leaves the pours nature of both materials exposed to the er factor that can compromise the basic properties of these materials.

Usually, all the cement, Concrete, Plaster and other cementitious product are used with water. It is a proven fact that water can not provide any additional strength if needed by the structure. In case of more cement doses are given to the structure, cracks, shrinkages and setting time are difficult to control

Let's see this with an example to understand in a better way:

Benefits of using Latex SBR in mortar:

In this modern world where high rise towers and skyscrapers are the need of the century, it's evident that building material makers play a key role in the development of futuristic and sustainable products.

It is gradually, yet progressively being perceived that financial advancement in the construction industry relies more upon the clever utilization of the materials and steady improvement of accessible materials than on outrageous refinements of structure.

We have given considerable effort to the development of Zeorich Latex (SBR). This additive is to be used along with construction mortar such as Concrete, Cement, plasters.

The advantages of Latex SBR:

- Reduces cracking through increased mortar flexural strength

- Increases wear resistance under rubber-wheeled traffic

- Improves bond strengths to hardened concrete

- Increases durability during freeze/thaw cycles

- Increases mortar tensile strength

- Greater bond with cement surfaces new or old.

- Improved abrasion on the top surface.

- Reduced water absorption from the surface.

- Water curing can be avoided or reduced.

- Resistant to thermal and seismic shock

Where can you use Latex SBR:

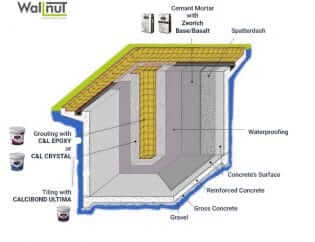

- Toppings, repairs, and levelling concrete surfaces

- Thin sets, terrazzo, stucco, and bonding coats

- General reconstruction work/latex-modified overlays

- Bridge decks, highways, and parking decks

Latex (SBR) mixing ration:

- As slurry bond coat 1:1:2 (Zeorich Latex: water: cement or Zeorich base)

- When mixed with plaster, mortar or screed: 1:1 (Latex: water)

- Water-resistance coating: No water dilution. 1:2 (Latex: Cement)

Conclusion:

Overall, the most important factors in the commercial viability of SBR making it a material of choice over water are:

- Wide availability

- Low cost compared with those of all other synthetic rubbers, plasticizer, additives

- Ability to accept high filler levels,

- Relatively stable price compared with that of NR and

- Overall properties on a cost/performance basis

Note: Refer to the product technical datasheet to determine the correct way to use the product along with other building materials