Why tiling grout joints/lines are so important in laying tiles:

Tiling grout is not the term lot of people have heard back in time but now people are aware of which material keeping our floors and walls safe over the years.

There are some international standards used all around the world by building mortar manufacturers to produce the grouts. We would suggest checking all these standards while in the early phase of your projects.

Now let us dive into some important facts about grout and how it has uplifted the tile installation process and increased the service life of the surface.

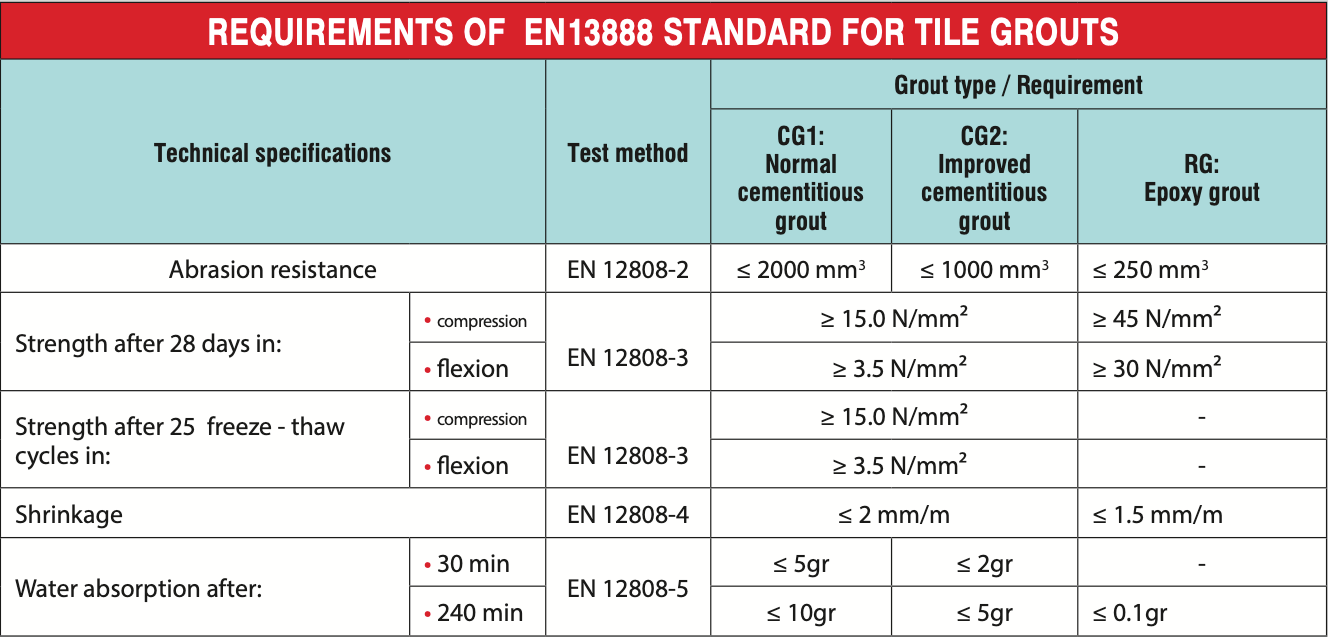

European Norm EN13888 STANDARD FOR TILE GROUTS

The fundamental characteristic of grout is not only to aesthetically elevate the design but to provide the strength and durability the ceramic tiling requires by eliminating the risk of cracking, Uneven flooring & detachment of tiles. These characteristics help in retaining the long life of tiles, planned and effectively filled joints can help broaden the life of tiles and keep the floor and walls long-lasting.

So how do we achieve this? The joint width of tiles is not the only matter of aesthetic preferences but a way of maintaining the manufacturing tolerance of tiles. This system between grout lines and tiles make the entire surface withstand more stress.

For example: If you are using a tile that is accurate in dimension, the grout line could be smaller than a tile that is not accurate in dimension.

In Accordance with British Standard 5385-3:2014, The grout width should not exceed the tile thickness unless more width is needed to hide some dimensional irregularities in the tiles, Or to create more decorative effects in the grout lines.

The depth of grout lines should be a minimum of 2/3 of the tile thickness.

The tile surface without the grout joints should be considered as the large format single tile as a result the surface will be more rigid which can crack due to the dimensional instability caused by the shrinkage (not completely cured during the tile installation), expansion & contraction in the substrate or tiling caused by changing temperature, shock and vibration.

To summarise: The surface with the right grout line will be able to absorb the setback of daily hammering and reduce the risk of breaking and detachment, thus improving the life span of your tiled floor and walls.

Selecting the correct grout is pretty much as significant as choosing the correct tile and adhesive. Before continuing, it is advisable to test its compatibility with tile and stone.

Grout selection criteria:

Application properties:

- Check the cleaning time by the manufacturer's guideline ( Time between grouting and setting and cleaning ).

- Service time (Duration after which new floor can be put onto service ).Pot life.

Shrinkage resistance:

- Should be able to prevent cracking.

- Any cracking, either in the grout line itself or between the grout and tile, should be considered as failure.

Compressive strength:

- Compressive strength is important for applications

Water absorption:

- Water absorption is pertinent to stain cleaning considerations

Chemical resistance:

- Chemical resistance becomes a key factor in the selection process to certain application and industries( Commercial Kitchen and Labs)

Abrasion resistance:

- Abrasion resistance is important for floor applications

Grout Classifications:

Grout Classifications: Grouts mainly comes in 2 types and classification of grout according to EN- 13888 and ISO 13007-3.

Different types of grout

Cementitious grout comes in 2 types - Sanded & Non-Sanded

Sanded Grout(Grout Normal Performance- CG1): Consists of finely graded aggregates, Portland cement, synthetic resins and coloured pigments added with water-retentive additive( Keeps grout moist till the time cement is not cured)

Non-Sanded (Improved Performance -CG2): Consists of very fine filler, synthetic resins, coloured pigment and water retentive additive.

Epoxy-based grout (Reactive Grout): Consists epoxy resin, silica fillers, pigments and a hardener. Epoxy grout is a waterless mix formulated by mixing a base material (part A) and a hardener (part B).

Grout for all kind of Tiles and Stone Joints:

The important aspect in deciding the right grout depends on the properties of grout and surface area.

Now a day the most popular and preferable grout is Epoxy grout due to its sheer Properties like chemical resistance, water-resistant, no absorption, aseptic making it a top choice among industrial flooring, commercial kitchen, chemical processing plant, labs, food processing plant, etc

in compliance with European norms-RG (Reactive Grout), Epoxy grouts are preferable when you require a product with no absorption, high resistance to chemicals and a high level of hygiene, such as in industrial floors, industrial kitchens, canteens, laboratories, etc.

All the products in the Connect & Lock series can be used for joints in floors, walls, work tables, etc.

High-performance, cementitious and flexible grout, such as Lite Grout & Stucco Grout product ranges, are normally used in surroundings where you require a high-performance product without reaching the same level of features as for epoxy grout.

Over the last few years, the epoxy grout has been topping the chart in-demand list for commercial as well as residential segment as tiling grout.

The large format tile has witnessed a sharp incline in the demand as compared to the previous years. As they are the top choice of Architects and Designer its imperative to use grout joints to reduce the high level of stress generated by the large format tiles and stone which, in turn, reduces the rigidity.

Crystal grout: Transparent epoxy grout for fixing and joint filling of multi-colour ceramic & glass mosaic. Also, joint filling for low thickness slab & other tiles & stone.

And it is just as important to choose suitable products to fill joints, products that have the right mechanical characteristics and properties, comply with international standards

Conclusion:

I hope this article has covered the important aspect of grout and joints. Now we all know joints has a significant role to play in the designing and installation of ceramic covering & their strong, durable and high-quality feature has a direct impact on the service life. it's really crucial to keep the design and tile dimension correct and as per the international standard.

This is my first time visit at here and i am really

happy to read everthing at single place.

Great delivery. Solid arguments. Keep up the great

effort.