Zeorich

Zeorich Base

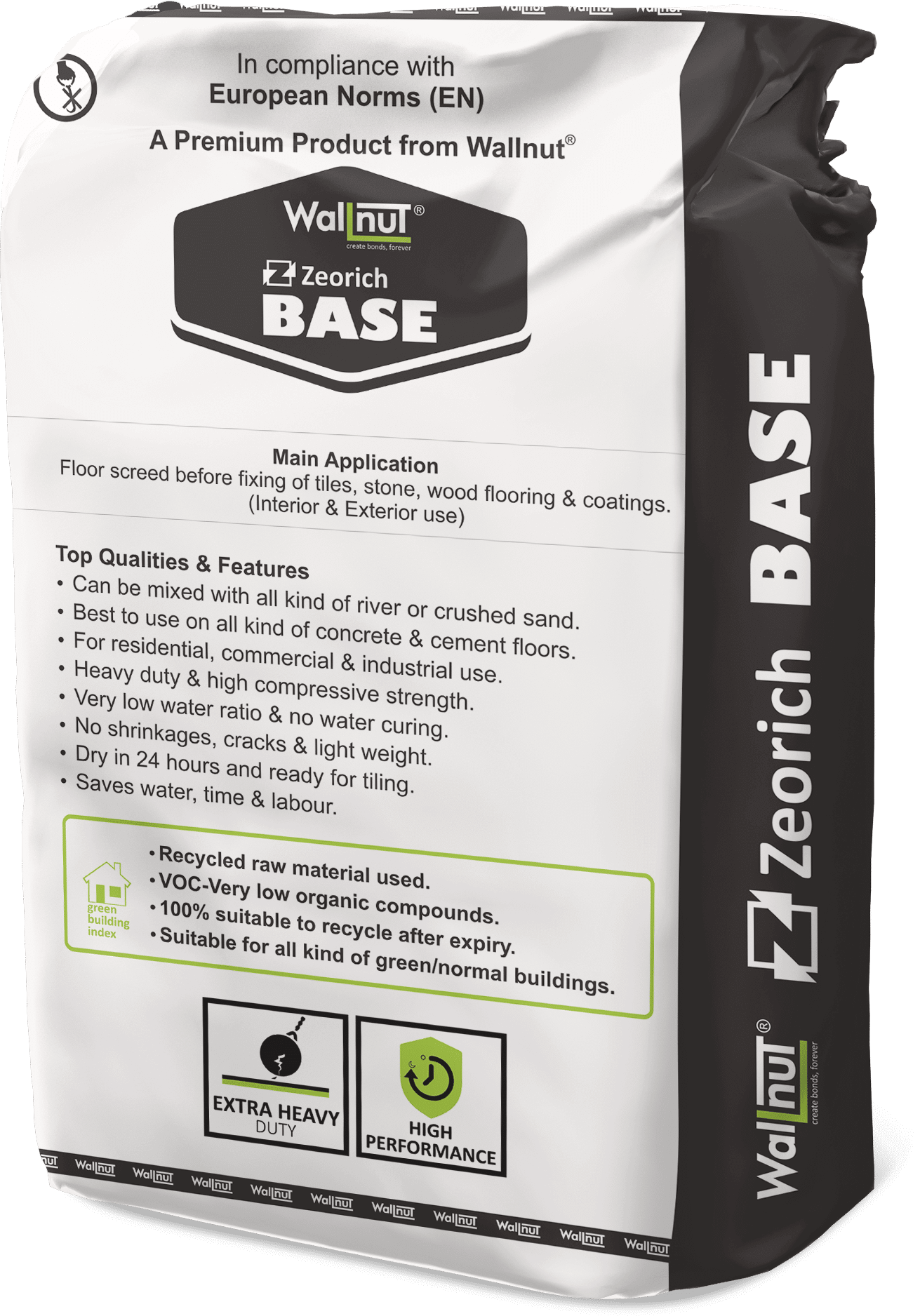

Zeorich Base(floor screed) is eco-friendly, lightweight, non-water curing, quick-drying, high strength, shrinkage-less, the mineral-based binder in powder form made from natural material to create a stable base of screed before fixing of any kind of tiles, stone, or other coverings such as carpet, wooden flooring, coatings, etc.

Available in

WEIGHT

- 20

KG

- 00

KG

- 00

KG

COLOR

PACK

In Compliance With

European norms

Zeorich Base(floor screed) is eco-friendly, lightweight, non-water curing, quick-drying, high strength, shrinkage-less, the mineral-based binder in powder form made from natural material to create a stable base of screed before fixing of any kind of tiles, stone, or other coverings such as carpet, wooden flooring, coatings, etc.

Binder for Underlay Screed for tiles, stone & other covering.

Zeorich Base Hi-Tech Features

- A Ready to use binder which replaces completely using traditional cement.

- Dry within 24 hours with humidity under 3% and ready for fixing of any kind of tiles or stable stone on top.

- No water curing requires.

- No moisture rising on the wall compared to traditional mortar and hence no peeling of paints

- No shrinkage in base screed, once fully dry in a short period of 4 - 5 days.

- Minimum thickness of 25 mm. till 80 mm. or more in a single go by adjusting sand size.

- Floor Screed can be used with any kind of river sand or crushed sand

- Low VOC and suitable for green building.

- Floor Screed can be used as fresh mortar to fix all kinds of tiles and stable stone by using Wallnut Lite Floor slurry adhesive.

- Heavy duty and compressive strength of >50 Mpa of a binder

- Wallnut floor screed can be customized at the site for desire compressive strength as high as up to 35 Mpa.

Suitable Areas For Zeorich Base

Advantage of Zeorich Base over cement mortar or Floor Screed

Residential & commercial parking.

Industrial floors.

Public infrastructures such as airports, railways, etc.

Internal & external floor as an underlay.

Fully wet areas including swimming pool, water tank, etc. as the underlay

Residential and Commercial open areas

How to Use Zeorich Base

- All kinds of ceramic & vitrified tiles with Wallnut suitable adhesive.

- All kinds of natural or recomposed stone with Wallnut suitable adhesive.

- All kinds of other coverage such as cement-based self-levelling, epoxy or PU coatings, wood flooring & carpet etc.

- Ensure that the concrete surface is sound, strong, clean, and free from all foreign material such as oil, grease, dust, etc.

- Before applying the products on extremely dry or hot surfaces, splash sufficient water to reduce the shock and surface temperature. Let it surface dry. In normal course too, splash the water to regulate the surface absorption.

- For dispersing the movement & stresses caused by expansion between concrete walls & floor, use a separator at all corners by using 5mm. thick and 4-inch-wide un-bonded polyethene foam sheet or similar kind of material.

- The expansion joint in concrete must be followed. In case of a large area of tiling, movement joint in a base mortar must be designed at every 3-meter along-with tiling.

- In the case of un-bonded mortar is required, first fix the 1 mm. thick polythene film on the concrete floor then spread the mortar in a thickness of 50 mm. or more and follow the tiling process.

- Mix the Zeorich Base preferably along with Zeorich Basalt sand as per the above-suggested ratio in a normal concrete mixer.

- The water ratio normally is 40 to 50 % by weight of Zeorich base but can be adjusted as per the type of sand, weather, and humidity until semi-dry consistency is obtained.

- If screed thickness is less than 40 mm. or the floor is under heavy use, apply first the slurry bond coat prepared with Zeorich Base: Water in the ratio of 3:1 by volume.

- If a slurry bond coat is applied, then spread the mortar onto the floor while still, the slurry is fresh.

Spread the mortar onto the prepared concrete floor in desire thickness, then compact and level. - Once proper levelling & compacting is done, especially for a large area, a lightweight power floater must be used to have a smooth and levelled surface. For small areas, proper smoothening must be done by using a flat trowel.

- Fix tiles or stable stone after 24 hours. In case moisture sensitive stone, wooden flooring, self-levelling, PU or Epoxy coating, use the screed after 4-5 days of full dry.

- In case tiles or stone to be fixed immediately by wet on wet technique, it can be done by using Wallnut Lite Floor slurry adhesive over fresh Zeorich screed and tiles or stone must be fixed within 1 to 2 hours of screed application.

Norms: In Compliance with EN 13892-2 for compressive strength

For Heavy Duty Screed : >/= 30 N / mm2 @ 28 days (Mixing Volume 1:4 : Zeorich Binder : Zeorich Basalt)

For Stone work Screed : >/= 22 N / mm2 @ 28 days (Mixing Volume 1: 6 Zeorich Binder : Zeorich Basalt)

For tiling Work Screed : >/= 15 N / mm2 @ 28 days (Mixing Volume 1:8 Zeorich Binder : Zeorich Basalt)

Coverage : From 1.5 Kg. M2 till 2.5 kg. M2 for each 10 mm. of thickness

Water ratio : 40% to 50% by weight of Zeorich Base OR more to prepare a semi-dry mix

Working Temperature : (Data@ 23℃. + 50% humidity)

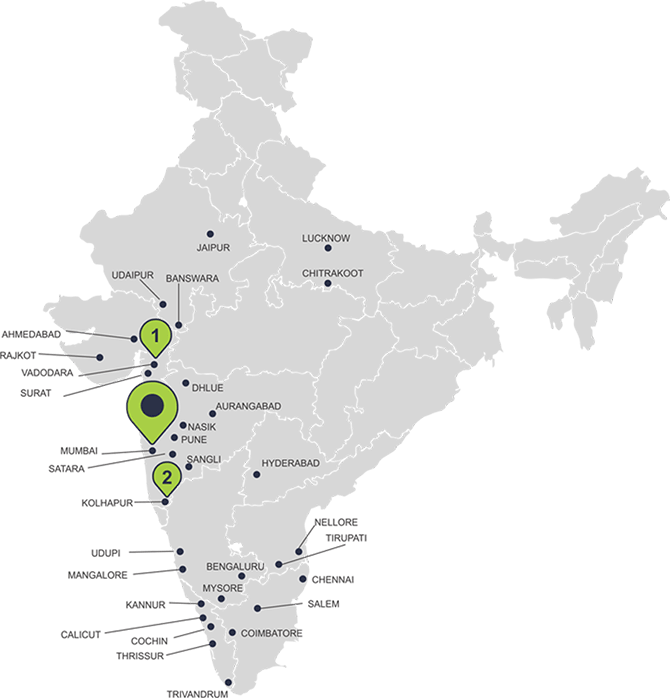

Keep in Touch

Get in touch for business and product acquisitions enquiries.

For Enquiries

91-22-49713322

91-9967007783

Email

info@wallnut.co.in